GORE® PHASEFLEX® Microwave/RF Test Assemblies for Defense Aircraft

Recognized among the 2020 Military & Aerospace Electronics Innovators Awards as a Gold Honoree, GORE® PHASEFLEX® Microwave/RF Test Assemblies have been trusted by the military and defense applications for decades. Providing unmatched repeatability, precision and durability over the life of the aircraft’s test system, our solutions are prequalified and tested to ensure they meet and exceed rigorous standards, as well as customizable to your testing needs.

Kontakt

+1 800 356 4622

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Unlike Alternative Test Cables for Defense Aircraft

Gore believes that microwave/RF test assemblies are among the top mechanical and electrical considerations aircraft operators, maintainers, engineers and manufacturers must make. That’s because a study has found that over 75% of microwave/RF cable assemblies worldwide are frequently replaced due to damage during installation, damage during use, poor quality assemblies, connector termination and outdoor environmental conditions.

GORE® PHASEFLEX® Microwave/RF Test Assemblies has been recognized among the 2020 Military & Aerospace Electronics Innovators Awards. Learn more

Instead of replacing your microwave/RF assemblies multiple times per year, choose the right microwave/RF test assembly that will lower your cost, time and risk. Though many assemblies share similarities in appearance and specifications, GORE PHASEFLEX Microwave/RF Test Assemblies are the only internally ruggedized, flexible test assemblies that:

- Guarantee consistently high performance and long service life in harsh aerospace testing environments

- Have a construction that’s durable enough to resist crushing, kinking and twisting, while also preventing potential damage from exceeding a cable’s minimum bend radius

- Maintain repeatable, accurate measurements and stable electrical performance up to 110 GHz

- Withstand frequent connecting and disconnecting

- Perform reliably after extensive flexing, with some constructions exceeding 100,000 flex cycles

- Provide excellent phase and amplitude stability with flexure and temperature

- Reduce aircraft downtime by increasing testing throughput and mission capable rates

- Lower costs and reduce risk for R&D and System Integration Laboratory (SIL) by enhancing confidence in data integrity and reducing re-testing and replacing

Applications

Reliable Performance across Various Defense Applications

With proven performance that is prequalified and tested before hitting the market, GORE PHASEFLEX Microwave/RF Test Assemblies provide trustworthy results in a host of defense applications, including:

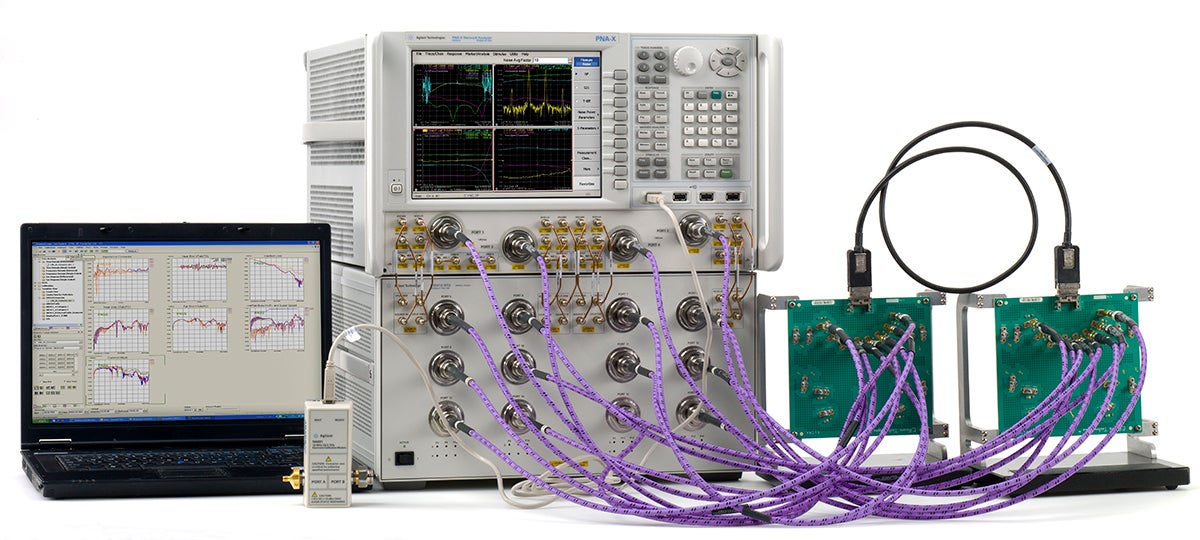

Courtesy, Keysight Technologies, Inc.

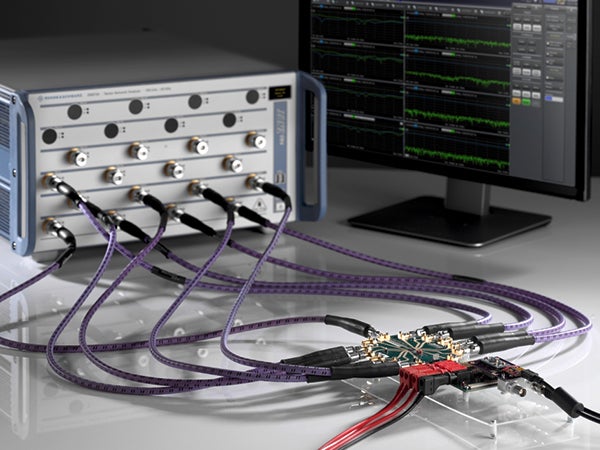

Application on R&S®ZNBT Vector Network Analyzer.

Courtesy, Rohde & Schwarz GmbH & Co.

- Antenna ranges

- Test rack systems

- Bench-top testing

- Portable analyzers

- Nearfield scanners

- Anechoic chambers

- High-speed digital test

- Scalar network analyzers

- Automated test equipment

- 5G test and interconnection

- Vector network analyzers (VNAs)

- Electromagnetic compliance testing

- High throughput RF production testing

- Environmental and vacuum test chambers

- Wireless telecommunication module testing

- And more.

Online Tools

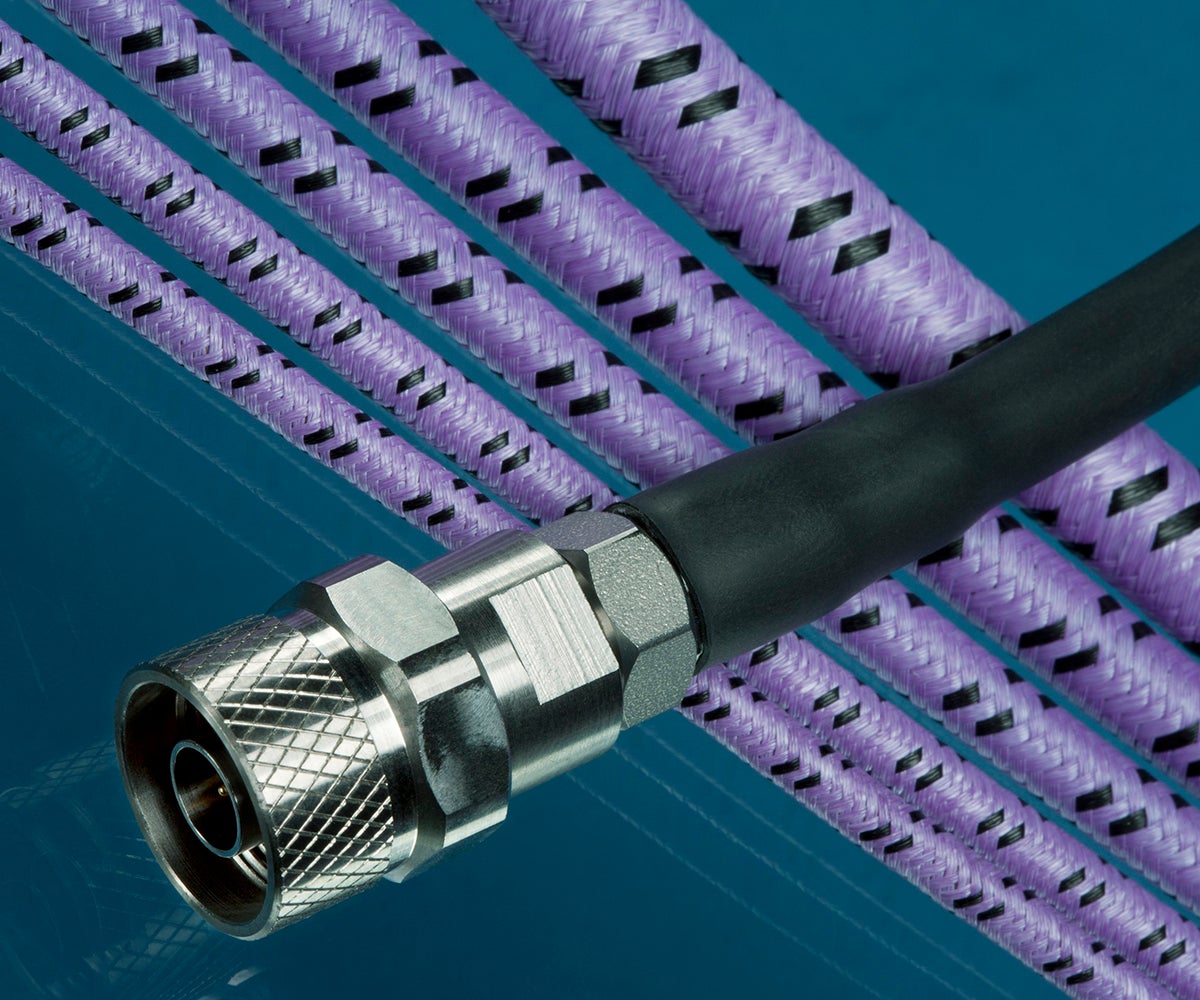

Construction of GORE PHASEFLEX Microwave/RF Test Assemblies

More Information

Learn More about GORE PHASEFLEX Microwave/RF Test Assemblies or Order Now

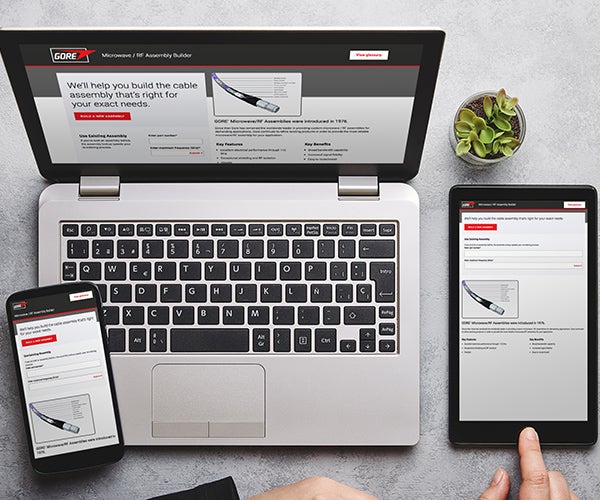

For more information or to discuss the specific needs for your defense application, contact a Gore representative today. We also invite you to review our products’ data sheet and visit our online cable builder, where you can design a cable that’s right for your applications and get a quote. Calculate insertion loss, VSWR and other parameters with our RF Calculator. Please contact one of our authorized distributors for in-stock availability.

Videos

Find more videos on Gore's YouTube Channel.

Resources

Article - Bringing Laboratory Performance and Precision Into the Field

Industry Articles,

View all resources for PHASEFLEX Microwave/RF Test Assemblies for Defense Aircraft

Aktuellste News

Pressemitteilung

The European Aviation Network Selects GORE® Microwave Sealed Airframe Assemblies for Durable and Reliable Signal Performance

Veröffentlicht: 6. Mai 2017

Gore is pleased to announce that starting this summer, GORE® Microwave Sealed Airframe Assemblies will be used to improve Wi-Fi internet access on European short-haul flights.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Verwandte Produkte

Cables & Cable Assemblies

Folge GORE® PHASEFLEX® Microwave/RF Test Assemblies for Defense Aircraft