GORE® Sterilizing-Grade Vent Filters

Designed to improve productivity by minimizing tubing kinking and other handling issues, GORE Sterilizing-Grade Vent Filters deliver the airflow of conventional 50 mm vent filters at a fraction of the size and weight.

Kontakt

Americas

+1 800 294 4673

+1 410 506 1715

Europe

+49 89 4612 3456

+800 4612 3456

US

+1 800 294 4673

+1 410 506 1715

Overview

Smaller, Lighter-weight Vent Filters for Sterile Gas Filtration

Problems during processing can be costly. When vent filters are large and heavy — as they commonly are — tubes can kink, reducing airflow or blocking airflow entirely. This can lead to losses during processing and lapses in productivity, while the large size of the vent filters can clutter a work area.

GORE Sterilizing-Grade Vent Filters are the smallest, lightest-weight vent filters available for use in small-scale sterile gas filtration today. At a fraction of the size and weight of the larger, heavier 50 mm vent filters commonly used in bioprocessing, our vent filters virtually eliminate handling issues like tubing kinking and limitations due to space constraints.

Manufactured in a manner that adheres to relevant current Good Manufacturing Practices (cGMP), our vent filters help ensure peak performance, and potential time and money savings, by doing more with less.

Commonly used 50 mm vent filters are heavy, weighing down tubing and blocking airflow.

Smaller, lighter-weight GORE Sterilizing-Grade Vent Filters address this common problem without sacrificing flow or retention.*

*image for illustrative purposes only

Availability

Efficient Design, Improved Performance

Gore offers unparalleled expertise in expanded polytetrafluoroethylene or ePTFE, an extremely strong, durable polymer that we use to power our vent filters. With our expertise, we’re able to engineer ePTFE membranes to possess performance characteristics that deliver.

Common Applications

Product Comparison

A Smaller, Smarter Solution

Commonly used 50 mm vent filters are heavy, causing tubing to kink and reduce or block airflow, which can lead to losses during processing. Typical 50 mm vent filters also take up a lot of space, making them difficult to manage in tight areas. Smaller, lighter-weight GORE Sterilizing-Grade Vent Filters virtually eliminate kinking while their small size helps reduce clutter in the work area.

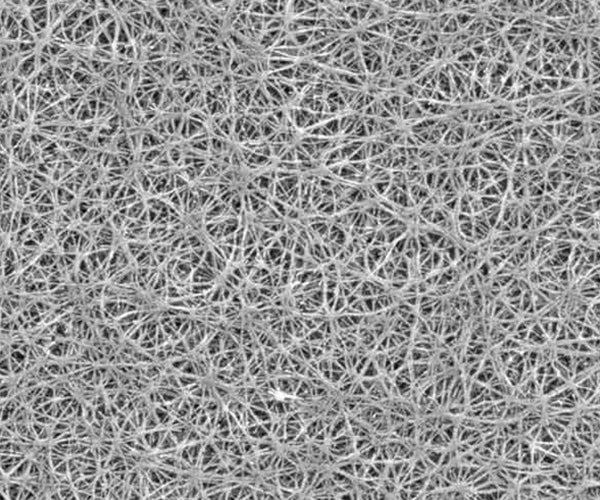

The Difference is in the Membrane

A close look at the GORE™ Membrane

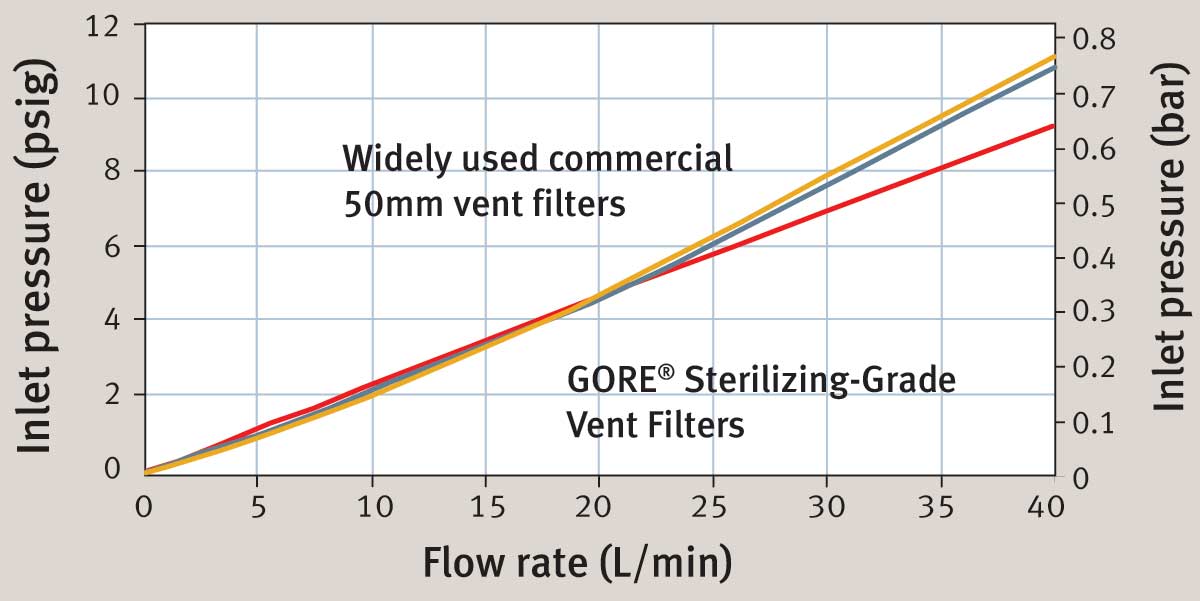

GORE Sterilizing-Grade Vent Filters provide airflow rates you’d expect from a filtration membrane area many times larger. In fact, our vent filters offer the airflow of other commercially available 50 mm vent filters — but in a smaller, lighter-weight package.

This performance is made possible by the superior high-flow, sterilizing-grade expanded polytetrafluoroethylene (ePTFE) membrane in each filter. Gore is the world leader in understanding ePTFE and its capabilities; we’re able to use that expertise to engineer the membrane to deliver the high-quality performance our customers expect.

Product Information

Comparison of Typical Airflow Performance

Performance Specifications

| Liquid Bacteria Retention | Retains a minimum challenge concentration of 1 x 107 cfu/cm2 of aerosolized Brevundimonas diminuta using a method based on ASTM F838-05 |

|---|---|

| Aerosol Bacteria Retention | Retains a total challenge of least 1 x108 cfu aerosolized Brevundimonas diminuta per device |

| Bubble Point | Equal to or greater than 12.8 psi (883 mbar) in 70/30% (v/v) mixture of isopropyl alcohol and water |

| Integrity Test | 100% tested prior to release |

| Biocompatibility | USP <87> Biological Reactivity Tests In-Vitro USP <88> Biological Reactivity Tests In-Vivo, Plastics Class VI |

| Physicochemical | USP <661> Containers — Plastics, Physicochemical Tests |

| Particulates | USP <788> Particulate Matter in Injections for Large Volume Parenterals |

| Bacterial Endotoxin | USP <85> Bacterial Endotoxin limits |

Detailed test information is available in the GORE Sterilizing-Grade Vent Filter Validation Guide, available upon request.

Operation

| Recommended Use | 0.25-inch (6.4 mm) inner-diameter tubing |

|---|---|

| Operating Temperature | 2°C – 40°C (36°F – 104°F) |

| Maximum Differential Pressure | 35 psid (2.4 bar), forward or reverse |

| Maximum Inlet Pressure | 40 psig (2.8 bar), forward or reverse |

Sterilization

Maximum of three autoclave cycles for 30 minutes at 135°C (275°F).

Note: Irradiation sterilization methods such as gamma or electron beam should never be used as they may damage or degrade the mechanical and barrier properties of the product.

Compliance & Quality

Gore is committed to providing our customers with rigorously compliant products that deliver high-quality performance over time. GORE Vent Filters are manufactured in a manner that adheres to relevant current Good Manufacturing Practices (cGMP) as defined in the Gore PharmBIO Products' quality system which is certified to ISO 13485 and ISO 15378.

A Certificate of Compliance accompanies each shipment of GORE Sterilizing-Grade Vent Filters.

For more information or to read our most current compliance statements, please contact us.

Resources

Aktuellste News

Event

Gore präsentiert innovative Filtrationslösungen auf der Carbon Black World 2024 in Wien

14. Mai 2024 - 15. Mai 2024

Treffen Sie die Gore Carbon Black Experten und führende Unternehmen der Branche auf dieser exklusiven Konferenz in Wien. Besuchen Sie unseren Stand (Nr. 9) und erfahren Sie, wie die innovative GORE® LOW DRAG Filterschlauchtechnologie unseren Kunden hilft, die Standzeit ihrer Filterschläuche zu verlängern und die Prozessstabilität bei verschiedenen Rußarten zu erhalten.

Event

GORE Mercury Control System – Vortrag auf dem 52. Kraftwerkstechnischen Kolloquium in Dresden

6. Oktober 2020 - 7. Oktober 2020

Das GORE Mercury Control System (GMCS) ist ein einzigartiges, fest eingebautes Sorbent-Polymerkatalysator-System für die Abscheidung von elementarem und oxidiertem Quecksilber in der Gasphase aus industriellen Rauchgasen. Es beruht auf einzelnen stapelbaren Modulen und kann nach Bedarf erweitert werden, um so die angestrebten Emissionswerte für Quecksilber- und Schwefeldioxid zu erreichen. Auf dem 52. Kraftwerkstechnischen Kolloquium (6. - 7. Oktober) in Dresden erläutert Business Development Manager Dr.

Pressemitteilung

CEZ setzt auf Gore, um die Quecksilberemissionen ihres Kraftwerks Mělník I in der Tschechischen Republik zu senken

Veröffentlicht: 29. Juli 2019

Neue EU-Vorschriften zur Begrenzung der Quecksilber- und SO2-Emissionen sollen bis 2021 in Kraft treten. Für Betreiber von Kohlekraftwerken ist es Zeit zu handeln. Eine bewährte, zuverlässige und kostengünstige Technik zur Emissionsreduzierung ist erforderlich, um die aktuellen und zukünftigen Vorschriften zu erfüllen und negative Umweltauswirkungen zu minimieren. Diesem Wäscher und der zweiten Linie können weitere Module hinzugefügt werden, um beide Linien mit den Bestimmungen der EU-Richtlinie über Industrieemissionen in Einklang zu bringen.

Event

GORE Quecksilberfilter auf der 19. VDI-Fachkonferenz “Messung und Minderung von Quecksilber-Emissionen”

26. März 2019 - 27. März 2019

Folge GORE® Sterilizing-Grade Vent Filters