GORE® Hook-Up Wires for Defense Land Systems

In difficult military surroundings, mission systems must be able to handle environmental and operational stress factors — and above all, not fail. With proven mechanical strength, Gore's robust hook-up wires maintain dependable electrical performance in a smaller, thinner, more flexible construction.

Kontakt

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Today's sophisticated electronic systems must maintain stable communications on mobile digital networks because failure is not an option with warfighters' lives and the mission at stake. So, hook-up wires need to be strong enough to withstand harsh conditions without ever breaking or failing.

GORE Hook-Up Wires deliver continuous power while transmitting high-quality signals, so troops can reliably communicate with each other during critical operations. We engineer our wires in a smaller design without jeopardizing mechanical strength or electrical performance. With specialized insulation materials, they can easily tolerate extreme environments, like low/high temperatures, harsh chemicals, complex routing, and severe vibration. These wires are also proven to reduce the risk of abrasion and cut-through.

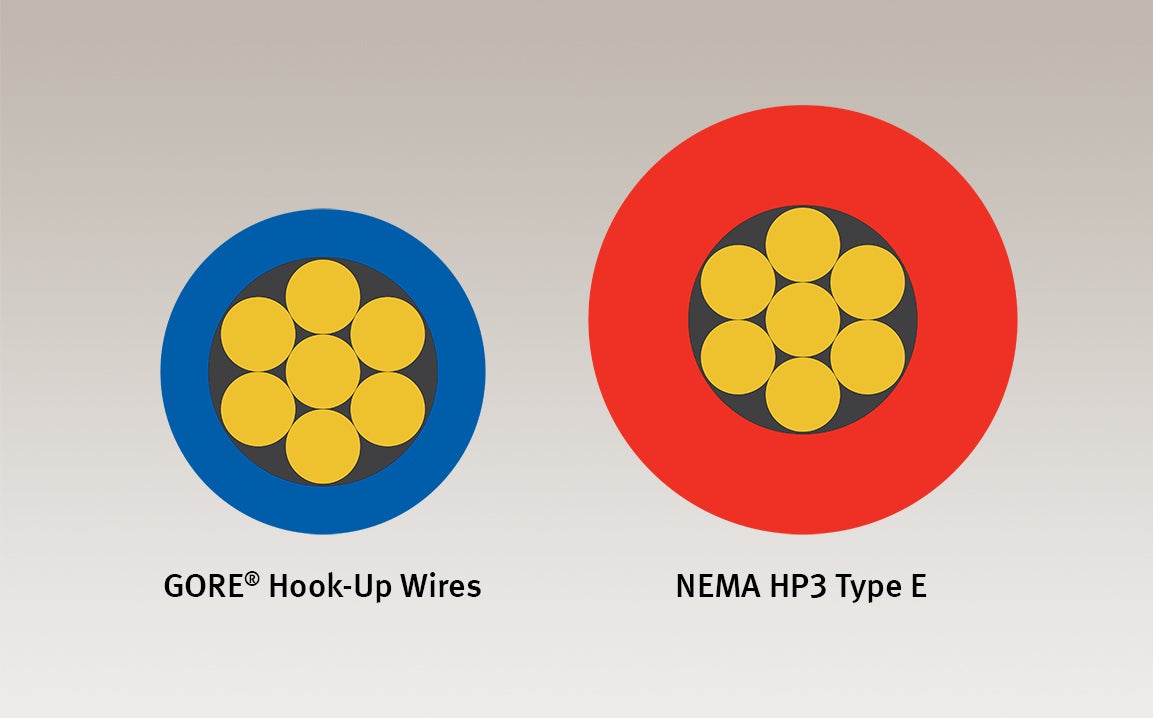

Gore's smaller wire design

Smaller wires with thinner insulation

As more high-tech electronic components are being installed in ground combat/support vehicles, there’s not as much room to route wire bundles.

Our hook-up wires are significantly smaller and require less space — more than 30% than a standard NEMA HP3 Type E wire — because of the thinner insulation that we use in the construction. So, wire by wire, they have a direct impact on saving weight. They’re also more flexible with a tighter bend radius making them perfectly aligned with today’s tight routing.

Whether your function is power or signal, GORE Hook-Up Wires provide the highest level of protection and performance in less space without short-circuiting. Ultimately, they reduce re-work, re-testing, and downtime due to wire failure — which means longer product life and less money you’ll have to spend overall.

Benefits

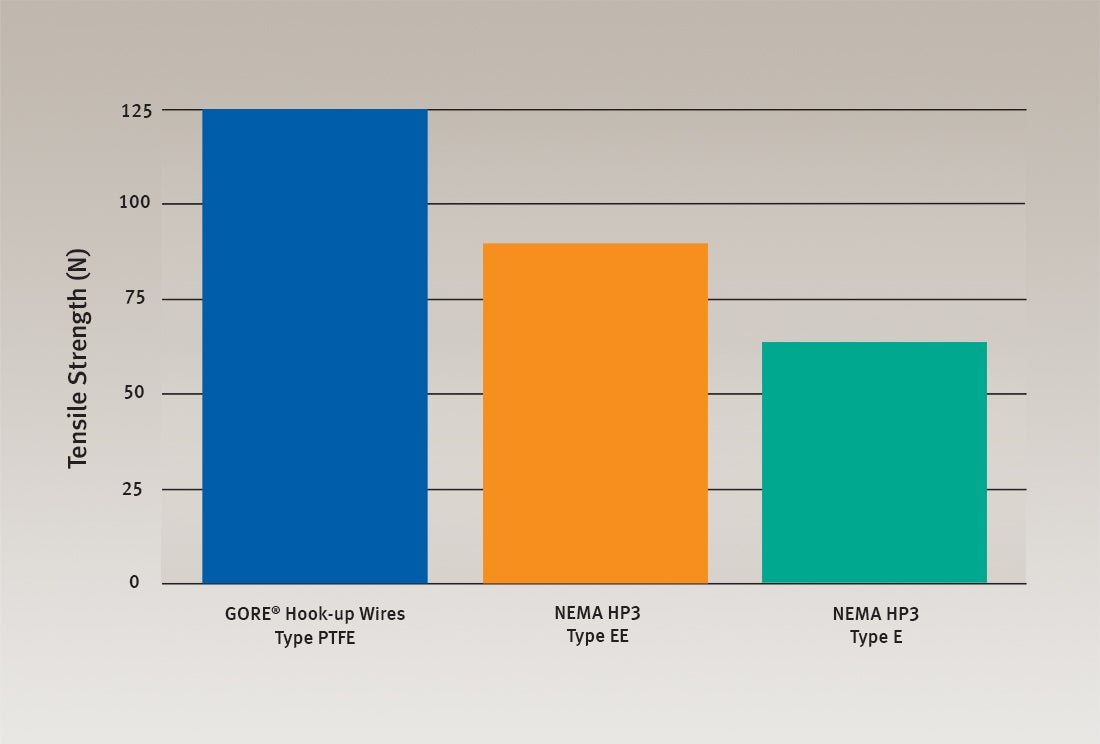

GORE Hook-Up Wires provide system architects and engineers with many benefits that improve electrical and mechanical performance such as:

- consistent power delivery with voltage ratings ranging from 100V to 1000V

- reliable signal integrity in severe conditions without short-circuiting

- superior cut-through resistance for added strength compared to standard NEMA wires

- enhanced durability due to temperature-/chemical-resistant insulation materials

- longer product life with abrasion-resistant and low-creep wire insulation

- smaller, lighter weight construction for improved installation and weight savings

- easier routing in confined areas due to greater flexibility and tighter bend radius

For more information about the benefits of our wires, please contact a Gore representative.

Type PTFE

GORE Hook-Up Wires with PTFE insulation are proven to provide a higher level of strength and protection while maintaining reliable electrical performance among critical mission systems.

Type Halogen-Free

With a unique patented primary insulation, this version of GORE Hook-Up Wires emits low smoke and no halogen when exposed to extremely hot environments. Our inherently non-flammable wires drastically reduce the amount of toxic/corrosive gases emitted during combustion while maintaining stable communications on mobile digital networks.

Resources

Aktuellste News

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Verwandte Produkte

Cables & Cable Assemblies

Folge GORE® Hook-Up Wires for Defense Land Systems